From driveways and patios to foundations and walkways, concrete is the most used material in both residential and commercial construction. But even the most durable materials can deteriorate over time. Understanding the common problems that can arise with concrete surfaces is the first step toward effective maintenance and repair.

Best Concrete Contractor in Conroe, TX

📞 Call: (936) 342-7242

📧 Email: info@conroeconcretecontractorstx.com

1. Cracks

Concrete surfaces can crack due to weather changes, settling, or pressure from heavy loads. These cracks not only affect the aesthetic appeal of your space but can also lead to more significant damage if not addressed.

Solution: Cracks can often be repaired with patching materials, sealants, or more extensive resurfacing depending on their size. For long-term durability, an experienced concrete contractor can assess the cracks and recommend the best course of action to prevent further damage.

2. Uneven or Sunken Concrete

Sunken or uneven surfaces are often caused by poor soil compaction or water damage. This common problem can create hazardous tripping hazards and disrupt the functionality of outdoor areas like walkways, driveways, or patios.

Solution: Leveling, also known as mudjacking or slabjacking, can restore your surface to its original position. Professionals can inject a stabilizing material under the surface to lift and level the surface without the need for costly replacements.

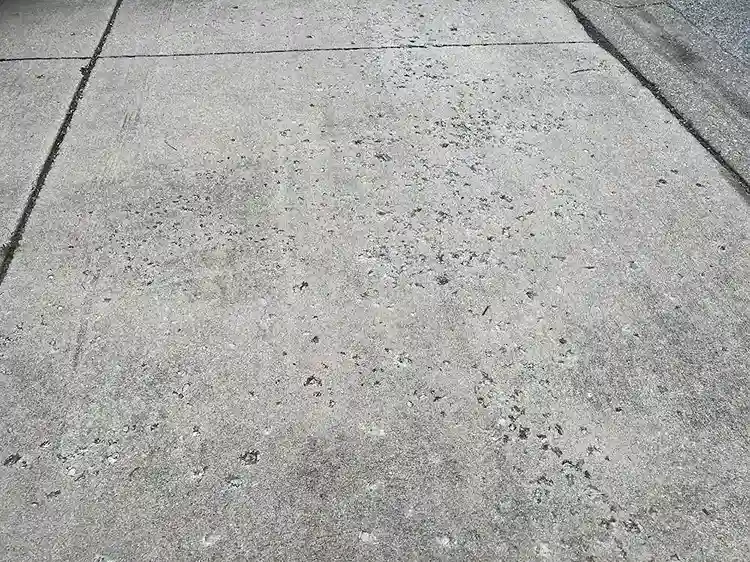

3. Surface Spalling

Sunken or uneven surfaces are often caused by poor soil compaction or water damage. This common problem can create hazardous tripping hazards and disrupt the functionality of outdoor areas like walkways, driveways, or patios.

Solution: Leveling, also known as mudjacking or slabjacking, can restore your surface to its original position. Professionals can inject a stabilizing material under the surface to lift and level the surface without the need for costly replacements.

4. Discoloration

Discoloration often occurs when the surface reacts with harsh chemicals, stains, or improper finishing during the curing process. This issue can make your surfaces look unattractive and uneven.

Solution: Professional cleaning, power washing, or staining can restore the appearance of your surface. In some cases, quality dyes or sealers can be used to even out the color, giving your driveway, patio, or flooring a fresh, uniform look.

5. Expansion and Cracking from Temperature Changes

Concrete expands and contracts with changes in temperature, which can lead to cracks if there is inadequate expansion space or control joints. It is especially common in areas with extreme weather fluctuations.

Solution: Control joints and expansion joints can be installed during the pouring process, which helps the cement shift with temperature changes without cracking. If cracks already exist, proper sealing and joint repairs can prevent further damage.

Long-Lasting Concrete Solutions for Every Project

Conroe Concrete Contractor provides expert services for all types of problems. Whether it’s installation, repair, or resurfacing, their team delivers high-quality solutions for both residential and commercial properties. With years of experience in Conroe and a deep understanding of local conditions, they are committed to ensuring your surfaces last for years.

Call Now To Get A Free Quote!

Contact Details:

Phone: (936) 342-7242

It depends on the severity of the damage and the quality of materials used. With proper care and maintenance, repairs can last several years.

For very small hairline cracks, DIY crack fillers might be sufficient. However, for larger or more complex cracks, it's best to consult a professional to ensure a proper and lasting repair.

The cost varies depending on the size and severity of the cracks. Call (936) 342-7242 for a free estimate.

Proper sealing and avoiding the use of de-icing salts can help prevent scaling.

Large cracks, uneven settling, and bulging are all potential signs of structural damage. Contact professionals immediately if you suspect structural issues.